High-Reliability Printed Circuit Board Manufacturer

Time-critical, High Performance PCB Solutions.

NetVia Group is a manufacturer of high-reliability, advanced printed circuit board technology. For more than 35 years, the most advanced and innovative technology companies have relied on NetVia Group for all their time-critical, high-performance PCB solutions. We specialize in multi-layer PCBs, rigid circuit boards, flexible circuits, and rigid-flex printed circuit boards that meet IPC-6012/6013/6018 Class 2, Class 3, and Class 3/A qualifications.

When your requirements demand attention to detail or when others no-bid the job due to complexity, this is where we find the opportunity.

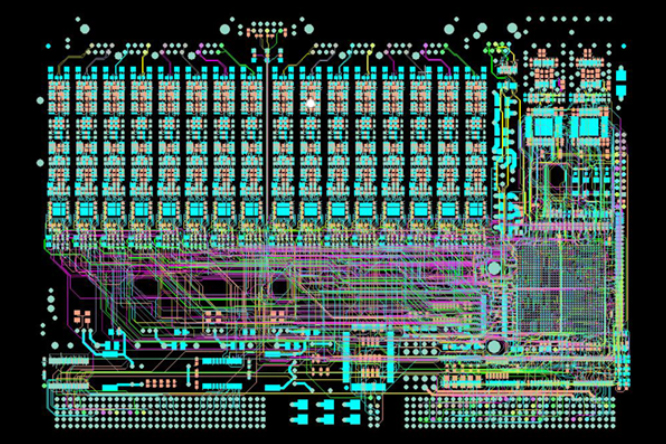

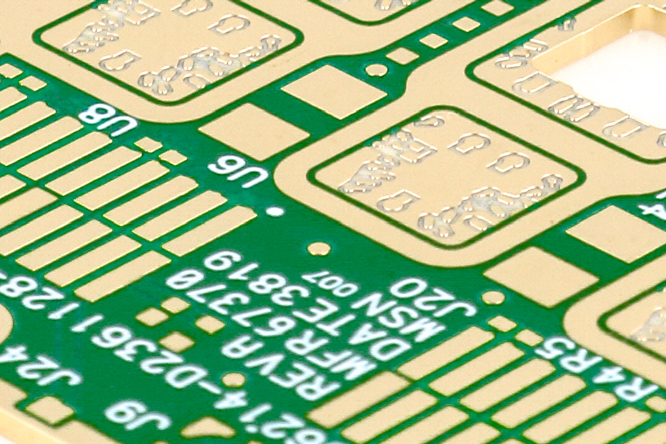

High-Technology & HDI PCBs

High technology printed circuit board designs utilize a combination of advanced features like microvias, blind vias, and via-in-pad, along with stacked and staggered vias to minimize the overall size of the PCB without sacrificing performance and functionality. With our continued investment in equipment, software, quality processes, and engineering, our customers can be confident that we can deliver quality product, on-time regardless of how complex the PCB may be.

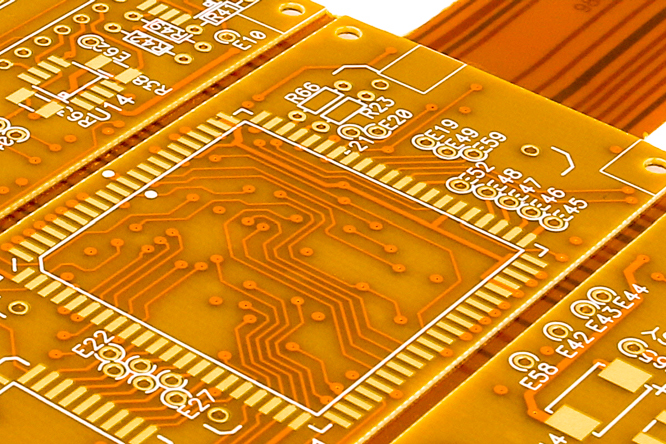

Request a QuoteAdvanced Flex & Rigid Flex PCBs

Flexible circuits and rigid-flex printed circuit boards provide a simple and reliable means to integrate multiple PCB assemblies and other components without wires, cables, or connectors. NetVia Group has extensive experience and the technical know-how in the design and manufacturing of flex and rigid-flex PCBs. Our products can be found in aerospace, military, scientific, and medical applications all around the world.

Request a QuoteAdditional Services

Engineering

We combine extensive engineering and manufacturing experience with the latest in software and equipment resources to produce the most complex PCBs to the customer’s exact requirements.

Technology

Our focus is on high-technology PCBs, which is why we have invested so heavily in our facilities. Blind/buried vias, embedded resistors, ENEPIG, via-in-pad, microvias, RF/microwave, edge plating, hybrid/mixed packages designs, and many more.

Speed

Our goal is to have the best lead times in the industry, and our team is committed to being flexible to help us meet customer demands. High-technology circuit boards have demanding specifications that require our team to move quickly without cutting corners in any way.