Solutions

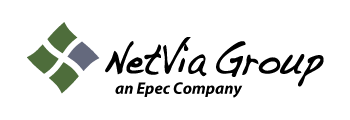

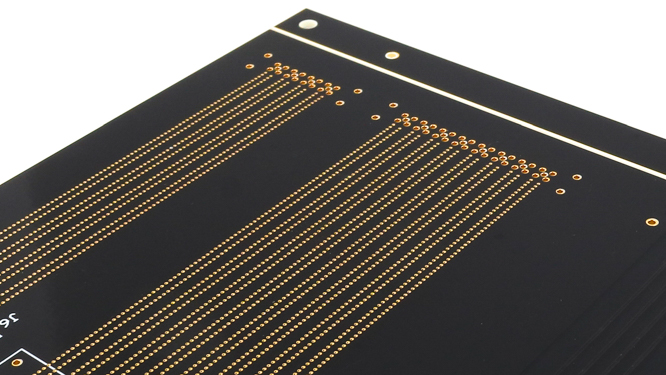

Advanced High-Technology PCBs

Day in and day out, we manufacture the most advanced high-technology PCBs that incorporate the most complex features in the PCB industry. We work with our customers at the very early stages of their product development to help them design a PCB that is both robust in features as well as being manufacturable. Having invested significantly in people, processes, and equipment, we have the technical know-how to ensure that we can deliver the most advanced PCBs with consistent quality and on schedule.

To ensure quality, all panels contain reliability coupons per IPC-2221 that are used for both in process and final inspection criteria. We can meet IPC Class III, MIL-STD-31032, and AS9100 requirements on any technology that we produce as we have all of the in-house laboratory and automated inspection equipment to ensure compliance. Many companies today try to focus and invest on being both a PCB fabricator and PCB assembler. Our strategy is to focus on being a world class leader in PCB fabrication and put all of our resources toward that single goal.

See our blog post on IPC Class III vs. MIL Spec for Printed Circuit Boards for more information.

Services

- Rigid PCBs up to 40 layers

- Quick-turns and Standard Delivery

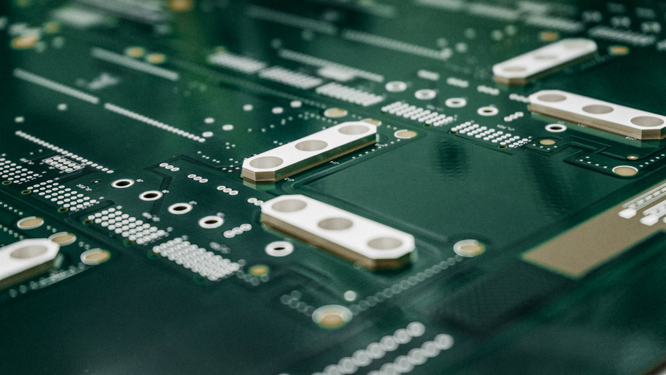

- Flex and Rigid-Flex PCBs

- Heavy Copper PCBs

- Embedded Resistors

- PCB Design Services

- Inventory Management

- Specialty RF & Microwave PCB

- Advanced HDI Circuit Boards

- Back Planes and Probe Cards

Our Parent Company, Epec Engineered Technologies is the ideal choice for an OEM seeking customized product solutions from a focused and agile partner having supported over 5,000 customers across all sectors of the electronics industry. By providing highly experienced technical resources, a proven manufacturing platform and the fastest delivery in the industry, we are able to provide cost effective and innovative solutions that deliver the highest reliability products to the market faster.

Technology

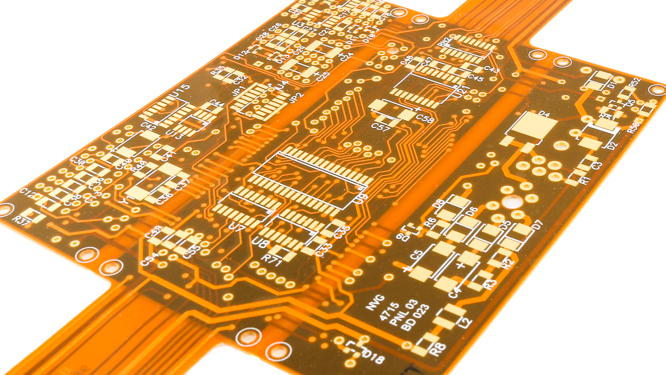

- Blind and/or buried vias, which account for approximately 40% of our work

- Conductive and non-conductive filled vias (i.e., VIP or via-in-pad technology), which accounts for better than 50% of the part numbers we build

- 100% Plated Filled Vias – specialized process

- Ultra-High Aspect Ratio (> 34:1)

- Controlled depth pockets, both plated and non-plated for various mechanical requirements

- Mixed package designs, where we bond and process different materials together

- Expertise in edge plating and castellation holes through a well-developed process

- Etched resistors on 25, 50, 100, and 250 ohms per square (Ticer and OhmegaPly)

- Electroless Nickel/Electroless Palladium/Immersion Gold (ENEPIG), in-house and regarded as the most superior surface finish available; also compatible with wire bond applications

- Microvias down to 0.004”, including 1+N+1, 2+N+2 and 3+N+3 stacked and/or staggered construction

- Copper and aluminum bonded boards for heavy thermal dissipation

Materials

- Rogers RO4350, RO4003, RO6035HTC, RO6002, RO3006, TMM and 2929 bondply material fabrication for RF applications

- Taconic RF-35, TLX/TLY, TSM-DS3b and Fastrise for RF applications

- Arlon DiClad, CuClad and CLTE for RF applications

- Panasonic Megtron 6 & 7

- Isola I-Terra, Tachyon, I Speed for RF/Microwave Low Loss applications

- Isola 185HR, 370HR and FR408HR for enhanced FR4 applications, including RoHS compliant as well as lower loss

- Polyimide multilayers for military, aerospace, and the oil and gas industries

If you would like more information about some of the common materials we use, we suggest you visit these websites:

- Arlon (substrates)

- Isola (substrates)

- Rogers (substrates)

- Taconic (substrates)

- Ticer Technologies (resistive materials)

- Ohmega Technologies (resistive materials)

Industries Served

- Defense & Aerospace

- Telecommunications

- Semiconductor

- Industrial

- Contract Manufacturing

- Medical

- Automotive

- Commercial